Introduction

Iron and steel scrap is melted in an arc furnace, brought up to

the expected specification through refining and then cast in moulds. The

operation has two basic furnaces: an electro arc furnaces (EAF) for

melting, and a ladle furnace for refining. Both furnaces use graohite

electrodes, which are shorted to the metal below, through an arc.

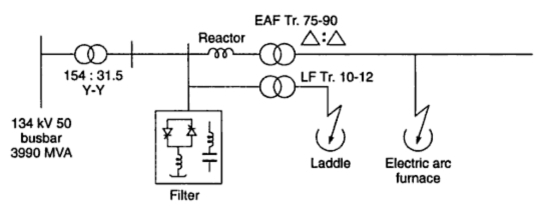

A general layout of an EAF installation is given in Fig. 1.

|

| Fig. 1 A general schematic layout of an electrical arc furnace installation |

On the application of high voltage across an air gap, the air in

the gap gets ionized under the influence of electrostatics forces and

becomes conducting medium. Current flows in the form of a continuous

spark, called the arc. When electrodes are made of carbon/graphite, the

temperature obtained is in the range of 3000 C-3500 C. The high voltage

required for striking an arc can be obtained by using a step-up

transformer fed from a variable A.C. supply.

an arc can also be obtained by using low voltage across two

electrodes initially in contact with each other. The low voltage

required for this purpose can be obtained by using a step-down

transformer. Initially, the low voltage is applied, when the two

electrodes are in contact with each other. Further, when the two

electrodes are gradually separated from each other, an arc is

established between the two.

Arc furnaces utilise the heating effect of an electric arc to

melt the contents of the furnace. They are characterised by very high

currents, perhaps up to 200 kA, at relatively modest voltages, between,

say, about 200 and 1000 V. Because of the power required by the furnace,

which might be between 10 and 100 MVA and occasionally even up to 200

MVA or higher, and the nature of the load, the transformers will need to

take their supply from a strong HV system. In the UK it has been found

appropriate to provide a supply to furnaces of up to around 120 MVA at

33 or 66 kV derived from a supply which is usually dedicated solely to

supplying a number of arc furnaces and having a direct connection to a

grid bulk supply point so that the disturbances created on the network

will be maintained at an acceptable level. For furnaces rated at 60 MVA

and above the bulk supply point needs to be associated at least with the

275 kV system. The relatively modest 33 or 66 kV HV voltage for the

furnace transformer has the benefi t of making the insulation level of

the HV windings and the tapchangers considerably lower and therefore

less expensive than they might otherwise have been..

Operation of a Furnace Transformer

It is desirable not to switch on and off a furnace transformer

too, often and particularly during a run. The output voltages of a

Furnace transformers range between 600 V and 900 V. A number of taps are

provided on the primary side. The variations of these taps helps to

maintain a steady high voltage across the electrodes during a run. A

steady high voltage is associated with a large arc length and a lower

anode consumption. The three graphic anodes are arranged in a mechanical

delta with well-maintained distances. This helps in maintaining a

balance between the phase voltages. It also helps in reducing the

production of harmonics.

Equivalent Circuit of 3-phase Arc Furnace Transformer

3-phase Arc Furnace Transformer includes an extended primary

winding with taps there in for the secondary voltage range

235-220-205-190-175-160 V, with primary winding connected in delta. This

voltage range is extended by changing the connections of the primary

windings from delta to star giving 58 percent voltage from each tap.

Fig. 2 shows the equivalent circuit of an arc furnace.

|

| Fig. 2 Equivalent circuit of an arc furnace |

RT = Equivalent resistance of the furnace transformer (referred to secondary side)

XT = Equivalent reactance of the furnace transformer (referred to secondary side)

RL = Resistance of the load,

XL = Reactance of the load

RE = Resistance of the electrodes,

RA = Arc resistance, and

EA = (= IRA) = voltage drop across the arc.

In order to exercise complete control of furnace temperature and

to achieve best-operating conditions both voltage and electrodes

controls are employed (The power input can be varied by raising or

lowering the electrodes, resulting in variation of RA and by changing the transformer tapping, resulting in variation of voltage across the furnace).

Conditions for Maximum output :

Power loss will be maximum when denominator is minimum

i.e., Power loss will be maximum when the arc resistance RA will be numerically equal to the impedance of the whole electrical circuit referred to the secondary excluding arc resistance RA.

''Power factor'' at maximum power loss,

However, it not economical to operate an arc furnace with primary side power factor 0.8 lagging.

Fig. 3 shows the performance characteristics of a typical arc furnce.

|

| Fig. 3 Performance characteristics of a typical arc furnace |

. Initially when the

electrodes are short-circuited, it is as good as short-circuiting the

secondary of a transformer. The total input to the furnace is almost

zero (copper losses in the transformer winding).

. when the electrodes are far apart arc is extinguished and there is no power drawn from supply.

In between the above limits there is a particular loading when the power input to the furnace is maximum.

great blog..

ReplyDeletefurnace repair services

As one of the trusted Industrial Gas Burner Suppliers India, Axis Thermal Furnace provides high-quality burners that meet demanding industrial requirements. Our burners ensure efficient fuel usage, uniform heating, and robust performance. With a wide supply network, we support manufacturing units, process industries, and thermal applications across the country.

ReplyDelete